Steam Production Control

Steam Production Control

In order to improve the steam production on board via the exhaust gas economiser, WinGD’s diesel-fuelled X-Engines can be equipped with a controlled exhaust gas bypass valve.

The valve can be opened when the exhaust gas temperature is lower than the target temperature, or when the steam pressure is lower than required.

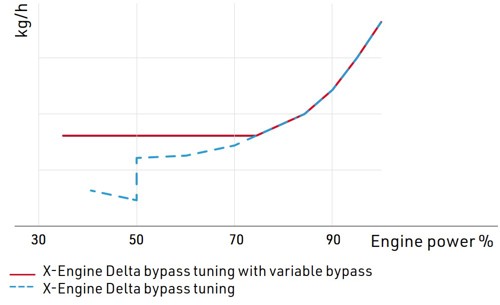

Once the bypass valve is opened, exhaust gas temperature increases and steam production through the boiler is increased. As an example, Figure 1 shows the same X-engine with and without the variable bypass.

With the variable bypass it is possible to target exactly the minimum steam production needed if the exhaust gas temperature is lower than required.

Without a bypass valve, operators would need to switch on the thermal boiler to reach the targeted steam production. Figure 2 indicates clearly that increasing the steam production with an engine variable bypass is more efficient than switching on the thermal boiler, and fuel consumption savings of 2–6 g/kWh are possible.

Steam Production Control

In order to improve the steam production on board via the exhaust gas economiser, WinGD’s diesel-fuelled X-Engines can be equipped with a controlled exhaust gas bypass valve.

The valve can be opened when the exhaust gas temperature is lower than the target temperature, or when the steam pressure is lower than required.

Once the bypass valve is opened, exhaust gas temperature increases and steam production through the boiler is increased. As an example, Figure 1 shows the same X-engine with and without the variable bypass.

With the variable bypass it is possible to target exactly the minimum steam production needed if the exhaust gas temperature is lower than required.

Without a bypass valve, operators would need to switch on the thermal boiler to reach the targeted steam production. Figure 2 indicates clearly that increasing the steam production with an engine variable bypass is more efficient than switching on the thermal boiler, and fuel consumption savings of 2–6 g/kWh are possible.

Gas technology

Find out more about the simple gas supply system that our X-DF technology uses, to reduce system complexity and auxiliary power consumption.

Environmental benefits

In a world of stringent emission targets, WinGD offers a smarter perspective. Find out more about the benefits of using benchmark, low-pressure technology to offer compliance capabilities and viable solutions for new regulations.